General (U)HPLC Troubleshooting Approach

Who hasn't experienced the following?

Suddenly the chromatographic results have changed. For example, peak deformation such as splitting or tailing occur, retention time shifts or nothing is detected at all.

Then it is time to find the cause of the anomaly and fix it. Because the final chromatogram is influenced by various factors, all the various components and variables should be examined in a systematically manner.

A systematic review of the following parameters is in order; each procedure will be described in more detail later in this document:

Download the YMC (U)HPLC Troubleshooting Guide here:

Problems in (U)HPLC and Their Cause / Correction

Back Pressure Changes

The root causes of back pressure changes can often be traced back to incorrect handling of samples and solvents which finally results in a blockage or contamination of system components and the analytical column itself.

No Pressure / Pressure too Low

| Potential Causes | Solution |

| Formation of negative pressure in the eluent reservoir |

|

| Leakage at piston seal or valves of the pump |

|

| Air or particulates in head of pump or valves of the pump |

|

| Leakage in transmission lines |

|

Increase in Pressure / Pressure too High

| Potential Cause | Solution |

| Blocked injector or capillaries |

|

| of water due to algae / bacteria |

|

| Blocked guard column or column inlet frit |

|

| Contamination of stationary phase |

|

Pressure Fluctuation

| Potential Causes | Solution |

| Leakage at piston seal or valves in the pump |

|

| Air or particulates in head of pump or valves of the pump |

|

Peak Broadening

| Potential Causes | Solution |

| Injection volume too large |

|

| Detection rate too low |

|

| Retention time too long |

|

| Viscosity of the eluent too high |

|

| Contamination of the stationary phase |

|

Fronting

| Potential Causes | Solution |

| Overloading of column |

|

| Viscosity of sample or mobile phase too high |

|

| Contamination of the stationary phase |

|

Tailing

| Potential Causes | Solution |

| Interactions of basic analytes with silanol groups |

|

| Dead volume |

|

| Ageing of packing material due to high temperatures |

|

| Blocked guard column or column inlet frit |

|

| Wrong pH value of mobile phase |

|

| Elution of a second sample component |

|

| Contamination of stationary phase |

|

Split Peaks

| Potential Causes | Solution |

| Blocked guard column or column inlet frit |

|

| Overloading of column |

|

| Inappropriate injection solvent |

|

| Dead volume |

|

| Elution of a second sample component |

|

| Carry-over of previous analysis |

|

Retention Time and Resolution

A change of retention time and resolution often is accompanied by a change in peak symmetry and efficiency. These are symptoms of a usual column ageing, but can also be caused by leakage in the system, problems with the injector, unstable temperature, or by contamination or damage to the stationary phase due to inappropriate method parameters.

Retention Time is Shortened

| Potential Causes | Solution |

| Overloading of the column (accompanied by too high /broad signal) |

|

| Ageing of the phase/ phase damaged by harsh conditions |

|

| Contaminated column |

|

| Elevated flow rate |

|

| For phases not stable in 100% aqueous conditions: dewetting of the stationary phase |

|

Longer Retention Time

| Potential Causes | Solution |

| Eluent composition has changed |

|

| Reduced flow rate |

|

Retention Time Shift in One Direction

| Potential Causes | Solution |

| Leakage of pump seal |

|

| Overloading of the column |

|

| Insufficient equilibration |

|

Retention Time Fluctuation / Random Shift

| Potential Causes | Solution |

| Temperature fluctuation |

|

| Insufficient solvent mixing |

|

| Wrong buffer concentration or pH value |

|

| Insufficient equilibration |

|

| From one system to another: Difference in dwell volume |

|

| Leakages |

|

| Defective pump valve |

|

| Air in the pump, air in the mobile phase |

|

Loss of Resolution

| Potential Causes | Solution |

| Contamination of mobile phase |

|

| Blocked pre-column |

|

| Ageing of stationary phase |

|

Spikes

| Potential Causes | Solution |

| Air bubbles in mobile phase |

|

| Air bubbles in column |

|

Drift to Higher Signal

| Potential Causes | Solution |

| Build-up and elution of contaminants |

|

| Mobile phase viscosity is too high |

|

| In gradient runs: increasing component B exhibits strong UV-absorption |

|

Drift to Lower Signal

| Potential Causes | Solution |

| In gradient runs: decreasing component A exhibits strong UV-absorption |

|

Noise

| Potential Causes | Solution |

| Wave-like noise: Temperature fluctuation in the environment |

|

| Continuous noise: detector lamp defect or detection cell contaminated |

|

| Periodic noise: air in pumps |

|

| Random noise: contamination |

|

| Spikes: air bubbles in detector, eluents or pumps |

|

Negative Peaks

| Potential Causes | Solution |

| RI-detector: refractive index of analytes lower than that of mobile phase |

|

| UV-detector: absorption of mobile phase higher than absorption of analytes |

|

Reduced Peak Area

| Potential Causes | Solution |

| Loss of sample due to leakage in injector, capillaries or connections |

|

| Reduced signal intensity due to contaminated or damaged flow cell/ old UV-lamp |

|

| Injection volume too low |

|

| High UV-absorption of eluent |

|

| Contamination of detector |

|

Column Regeneration

Accumulation of contaminants on the stationary phase are a common reason for adverse effects on column performance. This usually manifests itself in

• Higher back pressure,

• Shift in retention time or

• Deformed peaks.

To avoid accumulation on the column, the use of pre-columns and appropriate sample preparation such as filtration or extraction is advised.

Cleaning procedures are an effective measure for column regeneration in case of adsorption which has already occurred on the material of the stationary phase or to prevent accumulation of contaminants in the first place. Because contaminants usually accumulate and remain at the column head, cleaning procedures should always flush the column in the opposite direction to he usual flow direction to remove the contaminants more easily and not spread them throughout the whole stationary phase. Sufficient cleaning can be accomplished with a minimum of 20 column volumes of appropriate solvent.

When choosing the appropriate solvent, properties of the contaminants as well as stability of the column used should be considered. Examples for suitable solvents depending on the contamination present are listed in the following table. Higher efficiency of the cleaning procedure can be achieved by increasing the column temperature. Depending on the solvent and the stability of the stationary phase 40°C – 90°C is an appropriate temperature range for this. For further recommendations follow the instructions of the column manufacturer, usually found in the Care and Use Instructions.

Removal of different contaminations

|

Contaminant

|

Salts

|

Non-polar substances

|

Polar substances

|

Proteins

|

||||

| Approach |

|

|

|

|

||||

Preventative Measures

General considerations:

• Frequent cleaning of system, column and injector

• Regular replacement of worn and damaged parts such as filters, frits and seals

to avoid contamination.

Additionally, troubleshooting can be simplified immensely by frequently recording a column journal. We recommend you record the identity of the column, number of injections, resulting backpressure, analytes and method used and regularly verify the quality of the column with the results of a standard test method. Switching of eluent bottles, error messages or other abnormalities should also be recorded.

A column journal can reduce the duration of troubleshooting from days to minutes and can additionally provide a way to track your productivity gain after the optimization of your method parameters.

A guard column or guard cartridge systems protects the main column from a build-up of contaminants by absorbing them before they can reach the column.

Therefore, guards prevent:

• fast and early ageing of the column

• shift of retention times

• peak deformation

• void formation in stationary phase due to pressure pulses

Guards should be replaced regularly e.g., when back pressure increases or retention times shift. With a general test method, you can record resolution, peak symmetry and back pressure under known conditions to evaluate the status of your column and guard.

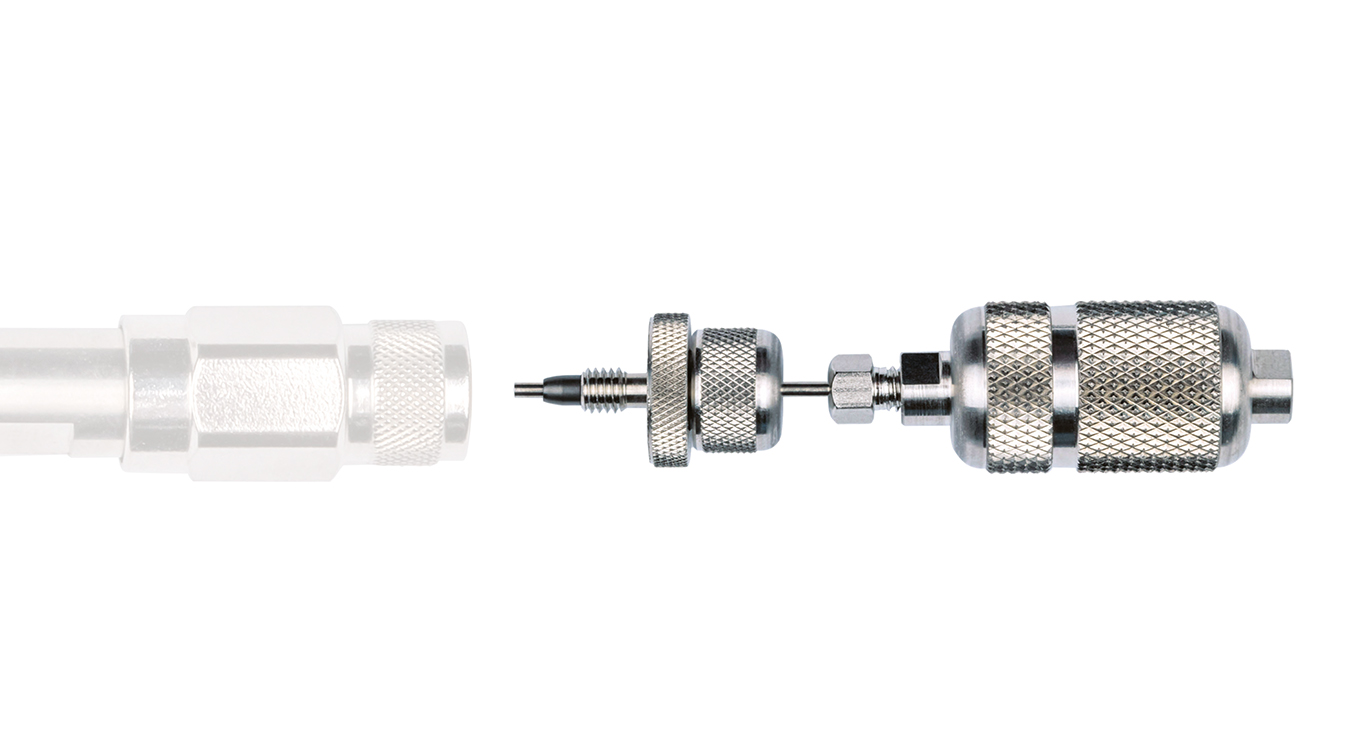

Especially in UHPLC applications additional column dead volume leads to band broadening. To prevent broad peaks due to non-optimal connections the use of zero dead volume universal connectors such as MarvelXACT is recommended. Additionally, all capillaries in the chromatographic system should be as short as possible.

HPLC/MarvelXACT-Fitting-System.jpg)

The sample solvent can have a strong influence on the quality of the separation and a suitable composition should be considered:

• Use a weak solvent composition for the sample ➔ or fronting of early eluting peaks

• Avoid large differences in the pH of sample and eluents ➔ or peak splitting

It is shown that without sufficient equilibration, retention times shorten significantly, whereas equilibration with 5 or 10 CV leads to a reproducible application.

How can the optimal equilibration duration be estimated?

➔ by means of the geometrical column volume!

The geometrical column volume is a useful parameter to estimate the necessary solvent volume for cleaning and equilibration steps in HPLC – a requirement for reproducible and valid results.

Calculation of column volume - Example

column: YMC-Triart C18

column dimensions: 250 x 4.6 mm ID

column volume [mL] = 25 cm × (0.23 cm)2 × 3.14

= 4.2 cm3

Additional considerations

Dwell Volume

• Volume of the system before solvent reaches the column.

• Dependant on system (ask the manufacturer)

Volume of the stationary phase

• Include correction factor (0.6–0.8)

• Dependant of stationary phase and packing density

Overview of geometrical column volumes [mL] for selected column dimensions

Technical Library

| Title | Document Type | Language | Download |

YMC (U)HPLC Troubleshooting Guide YMC (U)HPLC Troubleshooting Guide |

Brochure | EN | |

(U)HPLC Method Parameter Quick Reference (U)HPLC Method Parameter Quick Reference |

Expert Tip | EN | |

A hidden cause for peak tailing of small acidic compounds A hidden cause for peak tailing of small acidic compounds |

Expert Tip | EN | |

Easy solution for distorted peaks in HPLC methods of the European Pharmacopoeia (Ph. Eur.) Easy solution for distorted peaks in HPLC methods of the European Pharmacopoeia (Ph. Eur.) |

Expert Tip | EN | |

Equilibration – As much as necessary, as little as possible Equilibration – As much as necessary, as little as possible |

Expert Tip | EN | |

Expert tip: Column regeneration Expert tip: Column regeneration |

Expert Tip | EN | |

Guideline to buffer selection for RP methods Guideline to buffer selection for RP methods |

Expert Tip | EN | |

How to improve the analysis of hydrophilic compounds How to improve the analysis of hydrophilic compounds |

Expert Tip | EN | |

How to improve the analysis of hydrophobic compounds How to improve the analysis of hydrophobic compounds |

Expert Tip | EN | |

How to protect your peptides from oxidation during HPLC analysis How to protect your peptides from oxidation during HPLC analysis |

Expert Tip | EN | |

Is your sample soluble in your mobile phase? Is your sample soluble in your mobile phase? |

Expert Tip | EN | |

Issues with basic analytes Issues with basic analytes |

Expert Tip | EN | |

Minimising carryover in oligonucleotide analysis by AEX Minimising carryover in oligonucleotide analysis by AEX |

Expert Tip | EN | |

Stability of mobile phase in oligonucleotide analysis with LC-MS Stability of mobile phase in oligonucleotide analysis with LC-MS |

Expert Tip | EN | |

Overview on YMC-Hardware Types in Combination with YMC-Phases Overview on YMC-Hardware Types in Combination with YMC-Phases |

Overview | EN | |

The Principles of BioLC & YMC BioLC Phase Overview The Principles of BioLC & YMC BioLC Phase Overview |

Poster | EN | |

The Principles of Liquid Chromatography The Principles of Liquid Chromatography |

Poster | EN | |

Allowable Adjustments to HPLC Methods in the European Pharmacopoeia (Ph.Eur.) Allowable Adjustments to HPLC Methods in the European Pharmacopoeia (Ph.Eur.) |

Technical Note | EN | |

UHPLC systems compatible with 1 mm ID columns UHPLC systems compatible with 1 mm ID columns |

Technical Note | EN |

Expertise Topics

YMC Expertise portal: This is what you get

Get to know our expertise area in detail and learn more about the advantages of our portal.

Register now

Benefit from our extensive expert knowledge for example through our online presentations or our numerous data and content for download or use our online calculators for digital calculations.